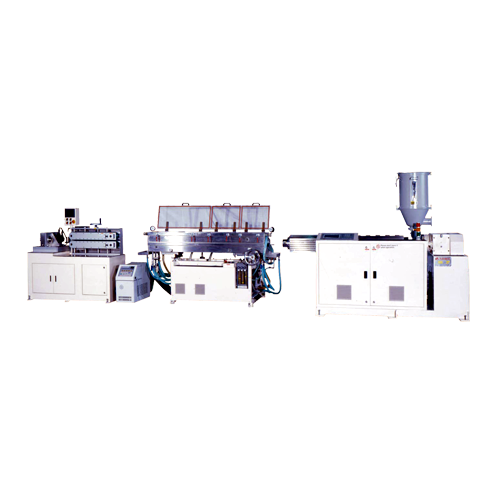

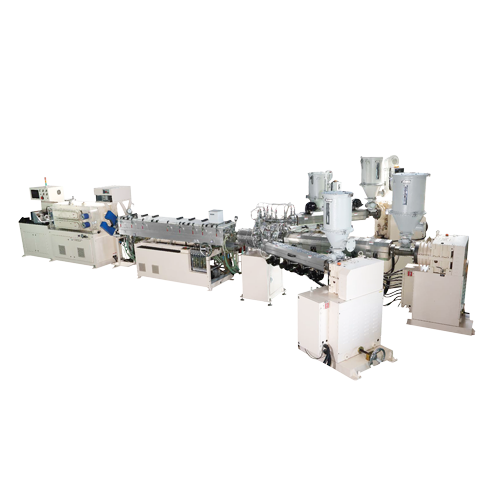

Extrusion is the first process of making PE tubes. This process ensures glossy surface, even thickness and well-balanced composition of plastic materials.

For years of research and development, our remarkable achievements on LLDPE & LDPE melting, screw design, device of die head, material adoption, and surface

treatment, together with size control by figuration and length restraint by encoder have produced valuable and high-quality tubes.

Screw dia: Ø50 mm

Screw L/D ratio: 30/1

Screw type: full flight

Main motor: 20HP with inverter

Heater: 17.5kw, 7 section control

Water consumption: ice water: 120 L/min, 5~10 ℃

Air consumption: 10 L/min

Power consumption: 58.5 kw

Extrusion linear speed:

Medium speed: 10 m/min (Ø35 mm) (EDC-08-01)

High speed: 20 m/min (Ø35 mm) (EDC-16-01)

Cutting speed:

Medium speed: 100 pcs/min (EDC-08-01)

High speed: 200 pcs/min (EDC-16-1)

Tube dia range: Ø16 ~ 60mm

Machine size: 7300 x 1700 x 2000 mm

Total net weight: approx. 2250 kg

Cutter PLC: Delta