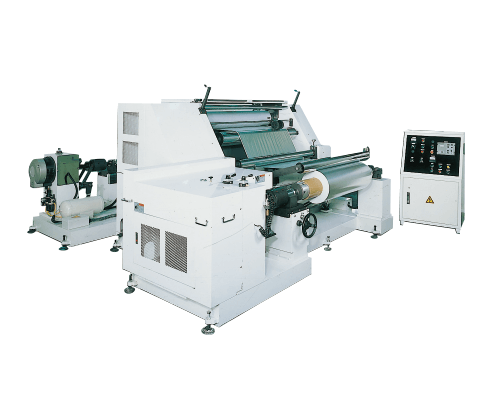

Classification : Embossing Machine

Country: Taiwan

Phone: 886-4-24832477

Fax: 886-4-24830852

Contact Person: Angela Chi

- Suitable for paper, plastic films.

- Perforation possible in straight and cross directions.

- Servo motor to maintain accuracy at 400 cuts per minute.

REF-B150 Series

| Model No. | REF-B150 | |

| MAX. PARENT WEB WIDTH | 1000-1500 mm | |

| MAX. PARENT WEB DIAMETER | 1000 mm | |

| THICKNESS RANGE | Depends on various materials' conditions | |

| MAX. REWIND DIAMETER | 1000 mm | |

| UNWIND/REWIND CORE I.D. | 3" ( Or as request ) | |

| MAX. MACHINE SPEED | 150 M/min. | |

|

INSTALLATION INFORMATION (For 1000mm standard machine) |

NET WEIGHT | 3000kg |

| AREA REQUIRED | L4075xW3081xH1865 | |

| POWER | As request | |

| WATER | X | |

| AIR | 6kg/cm3 | |