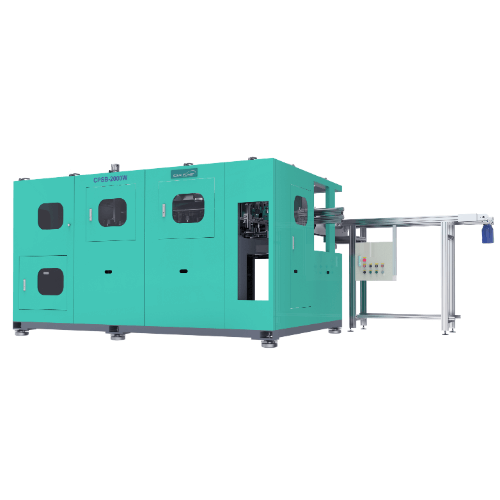

Classification : PET BLOW MOLDING MACHINE

Country: Taiwan

Phone: 886-4-23345536/ 86-595-88169879

Fax: 886-4-23345539/ 86-595-88165687

Contact Person: Claire

- Adopt the touch screen control system with 64K color and friendly PLC operation.

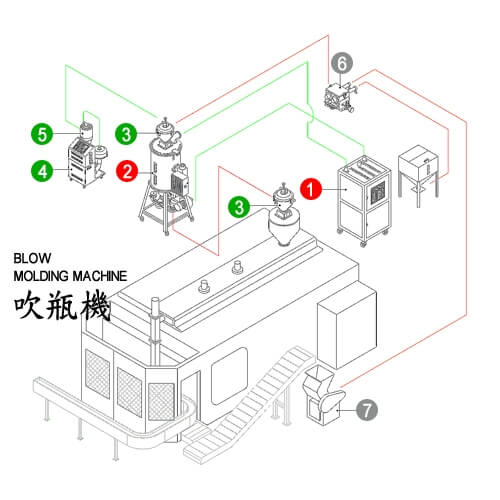

- Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system.

- The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste.

- Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly.

- The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating.

- Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method.

- With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems.

- Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp.

- The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution.

- Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

|

Model

|

EM04S2-88 | EM06S2 | EM08S2 | EM08S2-88 | EM04M1 | EM04M2 | EM06M1 | |

| Cavity no. | cavity | 4 | 6 | 8 | 8 | 4 | 4 | 6 |

| Theoretical Output | BPH | 6000 | 9000 | 12000 | 11000 | 5300 | 5300 | 7800 |

| Preform Holder | pcs | 128 | 168 | 224 | 224 | 120 | 144 | 168 |

| Heating pitch | mm | 54 | 54 | 54 | 54 | 54 | 54 | 54 |

| Cavity pitch | mm | 88 | 80 | 80 | 88 | 128 | 128 | 128 |

| Bottle volume | Max. | 1Ltr. | 0.75Ltr. | 0.75Ltr. | 1Ltr. | 2Ltr. | 2Ltr. | 2Ltr. |

| Preform neck | Max. (mm) | 38 | 38 | 38 | 38 | 38 | 38 | 38 |

| Preform height | Max. (mm) | 100 | 100 | 100 | 100 | 160 | 160 | 160 |

| Bottle diameter | Max. (mm) | 80 | 70 | 70 | 80 | 115 | 115 | 115 |

| Bottle height | Max. (mm) | 262 | 240 | 240 | 262 | 320 | 320 | 320 |

| Oven no. | box*channel | 1*2 | 1*3 | 1*4(2*2) | 1*4(2*2) | 1*2 | 2*2 | 1*3 |

| Heating power | kW | 32 | 50 | 62 | 62 | 44 | 82 | 74 |

| Installed power | kW | 44 | 62 | 74 | 74 | 56 | 94 | 86 |

| Machine size | cm | 430*410*290 | 300*260*290 | 390*330*290 | 540*510*290 | 340*320*290 | 340*320*290 | 430*320*290 |

| Machine wt. | kg | 5500 | 7000 | 7500 | 7500 | 7000 | 7000 | 9000 |

| Origin | Taiwan | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| China | ◎ | ◎ | ╳ | ╳ | ◎ | ◎ | ◎ |