Exclusive Interview with CHANG WOEN

Journalist: Verania Yang

Translation: David Boulter

CHANG WOEN

CHANGWOEN is one of the premier recycling equipment manufacturers in Taiwan. The way being outstanding and remarkable in recycling machine industry which differentiates from other manufacturers, is through their after sales services. They see themselves with a quality more on a par with the German manufacturers and are very particular when deciding on who to cooperate with and who will represent their products. Even though they have 15 representatives around the world, they only have 3 exclusive agents. One in South East Asia, one in Japan, and now in order to expand into the great European market they have started a partnership with REC-LINE from Italy.

Into the European Market

CHANGWOEN has been thinking about entering into the European market for a long while, but breaking into it in the right way is of upmost importance. According to Stefano Zecca, the REC-LINE sales manager, Europeans don’t know the difference between Chinese and Taiwanese products, they have a prejudice against products from this part of the world as being low in quality and not good enough for their needs, so even if the products are of a high quality and standard, if they are sold and branded through a European agent then they will have more success. This is why they have worked on a brand name and partnership. Selling as CHANGWOEN wouldn’t be enticing to the European customer, so together they came up with the brand REC-LINE to sell CHANGWOEN products in Europe which is 51% owned by Italian side and 49% owned by Taiwanese side. All products checked by Italians, assembled in Italy and with technical assistance provided by Italians, means that Europeans will be more willing to accept the quality of the products without preconceived bias.

CHANGWOEN and REC-LINE met at the 2013 Miami fair show and after an arduous process of deliberation and quality checking, they decided to work together to enter into the European market.

There are many reasons for the partnership but the three main reasons that CHANGWOEN chose REC-LINE are because of the technical expertise, industry contacts and most importantly because the after sales service that REC-LINE will be able to provide. Ted Kao a field application engineer from CHANGWOEN has a goal of resolving any customer issue within 24 hours, Stefano also agrees that this is a leading concern of European clientele, they don’t want to be waiting for weeks for an expert in Taiwan to get a visa to check the machinery and that is one of the issues that their company can resolve. REC-LINE also took a lot of time before deciding to cooperate with CHANGWOEN. Quality and technical ability of the foreign supplier is very important, because while there may be a lot of Chinese or Taiwanese suppliers, but only a few really have high quality. After looking at all of the options, REC-LINE decided that CHANGWOEN has the quality to match or even surpass the European standards.

About REC-LINE and the European market

Stefano stated that there are 10 people in REC-LINE and some support technicians and engineers from other companies. The price of oil is very low at the moment, so the recycling industry short term outlook isn’t very positive. This is not likely to change in the near future, so at the moment processing the raw material costs less than recycled material. There are however still opportunities especially in the European markets with governments providing subsidies to companies that help to reduce the amount of waste plastic.

How will they work together?

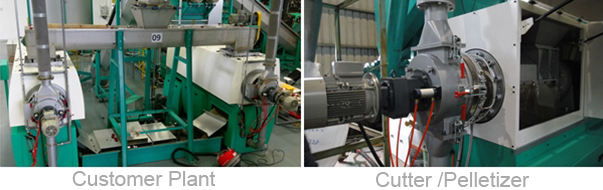

Ted explained that in order to have a closer relationship with REC-LINE, they will work together in marketing, financial support and after sales service. There is also a warehouse in Italy that is going to be supplied with spare parts for the machinery so that they can provide the 24 hour services that the customers’ desire. Stefano also explains further that, the issue in the European market is not that Taiwanese manufacturers don’t have the ability to meet the expectations of potential clients, but because they don’t know what these expectations are. Taking 2 examples, one is that, most of potential clients would like to have trail on the machine testing before they buy this machine. Can CHANGWOEN do it? Yes definitely CHANGWOEN can do it, he just didn’t know at beginning either who can help on this matter until CHANGWOEN meets REC-LINE, and REC-LINE help to set up show room in Italy. The other one is that, European customer cares more about tolerance of the machine. More specifically, the machine shall be designed with bigger power in order to receive any unexpected factors accidently during recycling activities. Can CHANGWOEN do it with bigger motor? Yes definitely CHANGWOEN can do it. He just didn’t know at beginning.According to Stefano another necessary requirement into successfully entering the European market is for the customer to be able to touch and test out the product before purchasing. Their European Showroom with machinery that the customer is able to see in action will address these concerns.

CHANGWOEN at K 2016

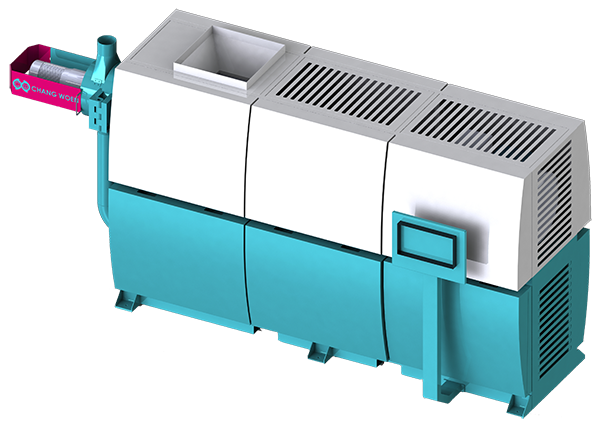

CHANGWOEN had a successful K-Show. There they showcased their newest development, a Squeezer that can help to solve the problem of film recycling. If you don’t get the film dry enough after recycling processing, film is easy to be twisted or folded, and further to get moisture trapped inside, not dried enough. If it’s not dry enough the capacity of the extruder to make pellets will lose a lot of efficiency. It doesn’t matter if it’s Chinese, Taiwanese or European, when compared on power consumption, ease of maintenance and performance, the new CHANGWOEN squeezer is one of the best on the market. Being able to leave the plastic with less than 3% moisture which is very useful to anyone who wants to process their plastic. The customers also have belief in this product. During the K-show CHANGWOEN had over 50 inquiries just for this specific machine and even sold 3 of their innovative and high quality squeezer machines on site at the K-Show.

The best Squeezer machine you ever met !!

Make sure recycler can remove moisture with our innovated machine. Features are:

● Less than 3% moisture remaining

● 500 kg ~1,000 kg per Hour

● Reversible Screw

● Energy Saving up to 15%

More Information on PRM: http://www.prm-taiwan.com/com/changwoen.html

Chang Woen Official Website: http://www.changwoen.com.tw/