Full Shine Plastic Machinery (TAIWAN) Presents the Updated & Customized Machinery with Robot Automation

** AUTOMATION TECHNOLOGY OF FULL SHINE BLOW MOLDING MACHINERY **

To seek the high production efficiency and less labor work, robot automation becomes the new trend and a must for all plastic factories in the near future. Robot automation ensures the high performance in the production line and avoids the labor shortage or increasing wage. However, in general, company owners have the misconception that to invest in automation means huge money. Nowadays, automation technology has become mature and cost effective. You can recover your investment in the short time by the practical way and even by thorough arrangement.

Today, FULL SHINE (TAIWAN) also approaches the automation in blow molding production. For your own customized design, Full Shine offers you several proposals in your production line. In FS-45HDSO, Full Shine’s linear movement blow molding machine installs the smart robot system to satisfy your ideal production. From auto deflashing process, carrying out finished bottles, and auto packing on trays, the whole process is done by the robot system. There is no need to have any labor involvement and less contamination. Full Shine also has many solutions for the automation in the plastic production line, especially design for your factory. To move forward on the automatic production line, this machine is capable of working on the whole line process, such as Auto Deflashing, Auto Jar Neck Cutting, Leak Testing, and Auto Recycling System for production automatically and Central Material Supply System Next By Machine, to achieve the concept of the condensed and complete production line.

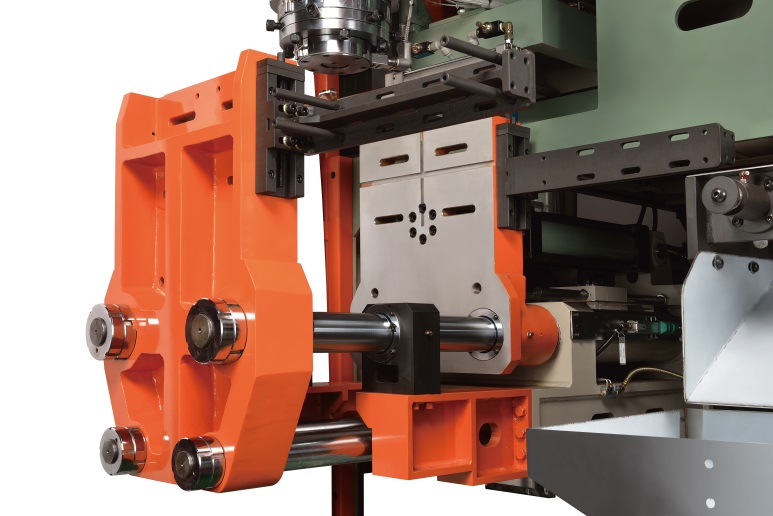

As better, FULL SHINE designs for the energy-saving concept by incorporating with Yuken-Japan Servo Drive System for Carriage as Energy-saving, providing the efficient Power Saving: 30-60%. With New Slide-Column Clamping Design for Strong Mold Clamping and Parallel Linear Carriage Movement. 100% made in Japan, as Energy-saving Unit, providing the efficient Power Saving: 30-60%. During the cooling time and idle time, the motor is at the sleep stage (extreme slow RPM, near to 0) to significantly reduce the max. power consumption, and when the motor is active, it start to the 100% performance. Incorporating with Yuken servo motor, the carriage movement is under the digital linear transducer control, which is more precise and accurate to ensure the molding performance in the exact positions and times.

With the efforts of the development and design department, Full Shine can produce the high-efficiency, energy-saving, customized-design and durable machines. Furthermore, Full Shine has a technical cooperation with PIDC, and develops multi-layers co-extrusion technology. In 2006, Full Shine was rewarded by the Taiwan government and received the research and development honor and in the same year, Full Shine was awarded the “Golden Hand Award” by the government in December which proved the great efforts of Full Shine in this field.

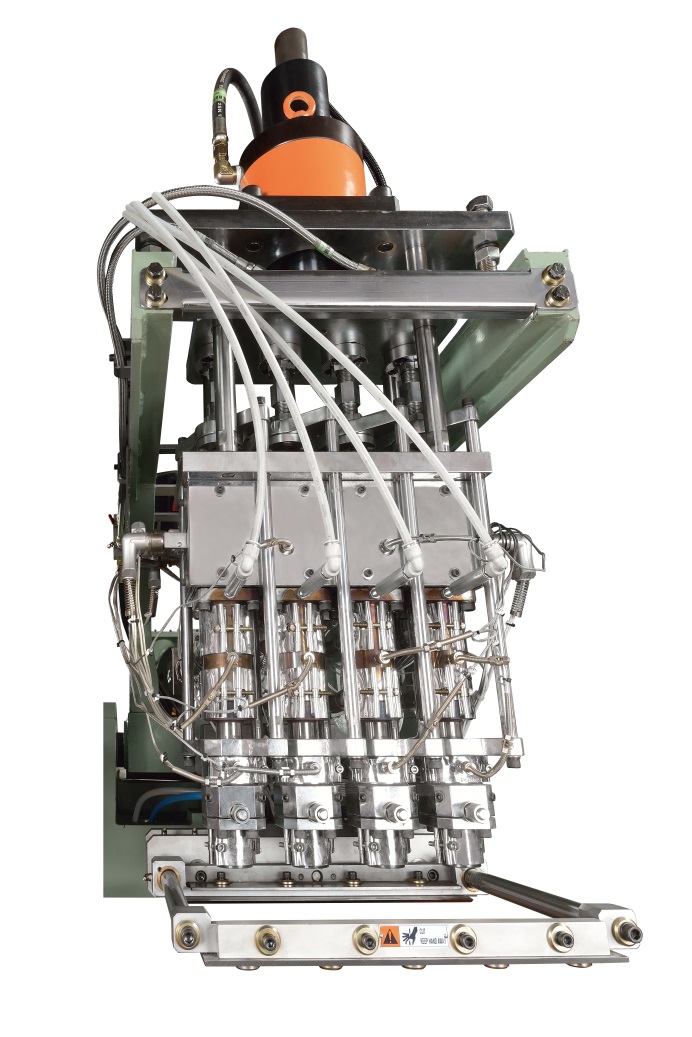

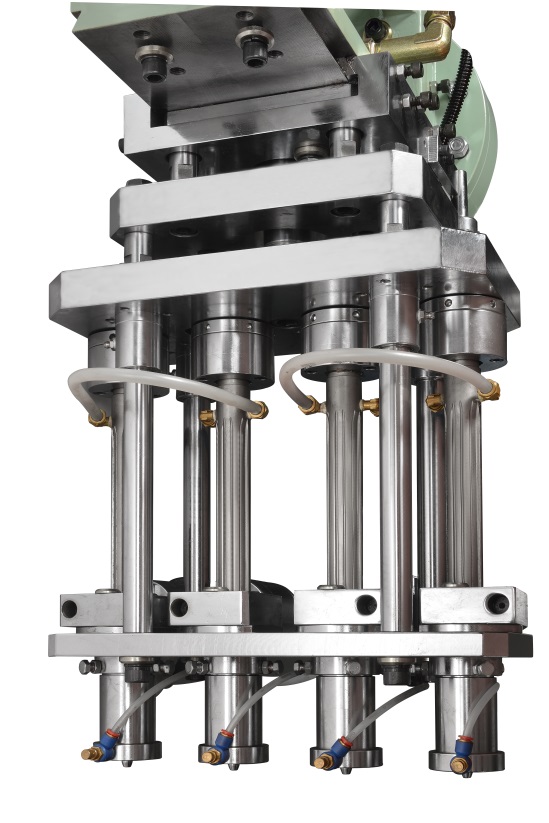

Full Shine combines practical experience and academic information technology industry, developing ofthe key technologies of co-extrusion. The multi-layer co-extrusion blow molding of plastic combined with different characteristics, such as 2 to 6 layers composite bottle or automobile components, with a combination of different plastics, play features layers of plastic in order to achieve high gas barrier properties, high resistance water-based, use of recycled materials ratio of more than 70% of the features.

For more about FULL SHINE, FULL SHINE plastic machinery always symbolizes excellence in making blow molding machinery. FULL SHINE has earned an excellent reputation for quality machines and thorough services around the world, selling to more than 50 countries. The key to our success comes from considerate services and quality assurance on FULL SHINE blow molding machines, coupled with efficient global marketing and competitive prices. Due to the support of our experienced personnel, innovative design, and quality-machine performance, our customers place complete trust and reliance on FULL SHINE. FULL SHINE never stops striving to maintain our regulative concepts: “Service from Heart; Achievement from Collaboration”. As the most active and competitive manufacturer in Taiwan, FULL SHINE has the ISO 9001 Certificate and CE Certificate on all machinery.

Full Shine Plastic Machinery, based on the concept of “Quality, Innovation, Professionalism and Consideration”, has established since 1992, is the professional manufacturer of Blow Molding Machinery in Taiwan. With the spirit of pursuing perfection, FULL SHINE devotes itself to innovating and improving the machinery, and strives for its best to provide customers with the excellent machine performance, high quality mechanism, sustainable management and best after-sale service. Full Shine machines are exported to more than 50 countries. Therefore, FULL SHINE has won itself the good reputation in the plastic molding industry field, worldwide.

**Products and service (Full Shine specializes below machines)**

1) Automatic Blow Molding Machine

2) Automatic Accumulative Blow Molding Machine

3) Automatic Co-extrusion Blow Molding Machine

4) One Stage Injection Blow Molding Machine

5) One Stage PET Injection Stretch Blow Molding Machine

6) Automatic and Semi-auto PET Stretch Blow Molding Machine

7) Integrate machines production in automation

8) Die head, Mold and optional equipment

In addition to provide these specialized machines, in response to the global trend, service and professional-oriented, FULL SHINE offers custom-designed machines and help customers to develop new products, the integration of machines and automated production, access to customers end of the high degree of satisfaction and certainly trust.

More Information on PRM: www.prm-taiwan.com/com/full-shine.html

Official Website: www.full-shine.com