Issue 56

Subscribe Now

High Torque, Innovative Design Gearbox

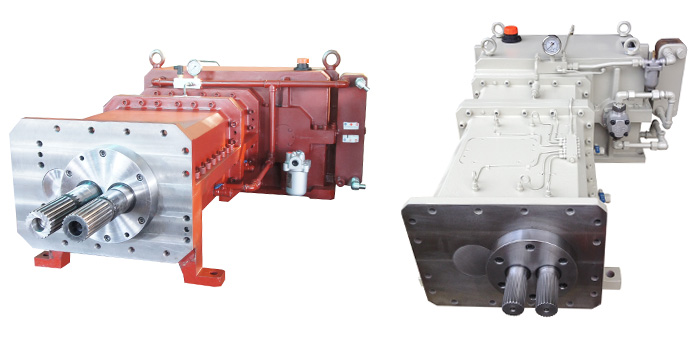

Gearbox for Twin-screw Extruder - Co-rotating / Counter-rotating

Double Helical Gear for Torsion.

It is manufactured as a single piece:

● Smoother gear operation

● No Axial Thrust Force

● achieves substantially more torque than other alternatives

● 100% Torque Output

Lower the Temperature Effectively

We set up cooling pipe inside to lubricate bearings, gears and other parts.

It will ensure your gearbox operating under optimal temperature.

The Oil Cooling System Includes

● oil pump

● heat exchanger plate

● oil filter

● oil pressure gauge

The Spline with Cylider Grinding

● gives you exceptional precision on positioning

● minimal hindering on screw operation

It is manufactured as a single piece:

● Smoother gear operation

● No Axial Thrust Force

● achieves substantially more torque than other alternatives

● 100% Torque Output

Lower the Temperature Effectively

We set up cooling pipe inside to lubricate bearings, gears and other parts.

It will ensure your gearbox operating under optimal temperature.

The Oil Cooling System Includes

● oil pump

● heat exchanger plate

● oil filter

● oil pressure gauge

The Spline with Cylider Grinding

● gives you exceptional precision on positioning

● minimal hindering on screw operation

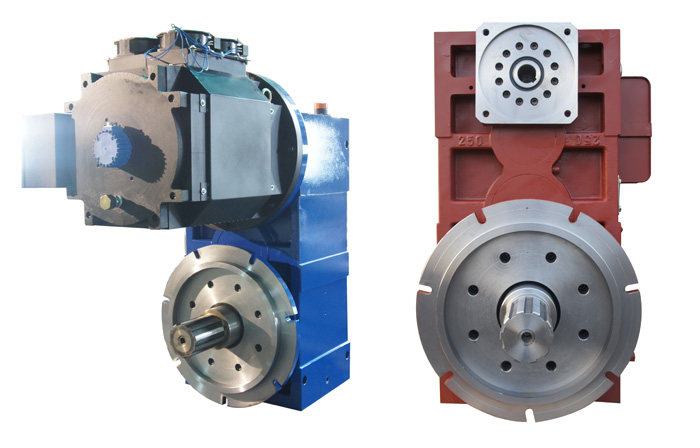

● advance 4 shaft design

● 4 shaft design extends the working life of your gearbox

● 4 shafts design requires less motor output, reducing power consumption, saving 50% electric bill than traditional hydraulic motor.

Compact Structure

● optimal for space-saving machine designs

● allows more work space on your machine table

● motor shaft can be connected directly to our gearbox, no additional adapter flange needed

Higher Efficiency of Productivity

● with Servo Motor to drive is easier to control

● inject with faster response, more precision and higher sensitivity feedback

● cycle time effectively shortened and improving production capacity.

COST DOWN

● no coupling needed

● lower power consumption, saving your electrical bill

● no consumables needed in operation, easy maintenance

● long- life for gearbox

Easy Maintenance, Easy Install

● Easy motor mounting. motor axle can be connected to gearboxes with some bolts

● Easy maintenance. No special tools required to disassemble. No irritating maintaining processes, just change lubricating oil regularly

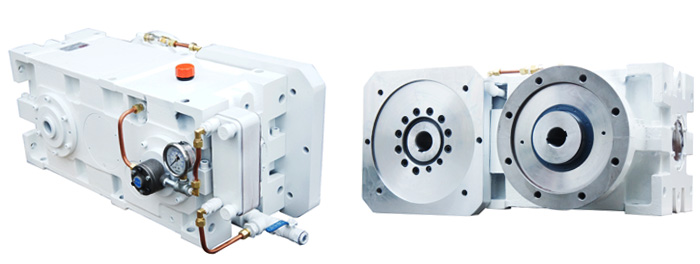

Three Stages Gearbox for Extruder

● advance 4 shaft design

● 4 shaft design extends the working life of your gearbox

● 4 shafts design requires less motor output, power consumption is lower than those of pulley

Compact Structure

● optimal for space-saving machine designs

● allows more work space on your machine table

● Motor shaft can connect to our gearbox directly

● it could fit different specifications

● barrel and motor could be on the same direction

COST DOWN

● no consumables needed

● no Coupling needed

● no adapter needed

● no drive pulley needed

● no drive belt needed

● electricity saving, also save your electrical bill

● easy maintenance

● long- life for gearbox

Easy Maintenance, Easy Install

● Easy motor mounting. Motor axle can be connected to gearboxes with some bolts

● Easy maintenance. No special tools required to disassemble. No irritating maintaining processes, just change lubricating oil regularly

About BSG

Founded in 1987, BSG Gear LTD is specialized in gearbox manufacturing.

We offer our customers complete solution, from design, development to production

of various gears and gearboxes. Our products are widely used in various

industrial applications, such as rubber & plastic extruders, metalworking,

paper converting and printing machinery. We would like to bring best possible

satisfaction to our customers. Therefore, every aspect of our management meets

ISO standards, highly precision inspection instruments are adopted for

stringent QC and all assembly are done by highly skilled technicians.

More information on PRM: http://www.prm-taiwan.com/com/bsg.html

Official Website: http://www.bsg.com.tw